Cs Astm A106 Grade A & B Seamless Pipe

Price 89.0 INR/ Kilograms

Cs Astm A106 Grade A & B Seamless Pipe Specification

- Material

- Mild Steel

- Application

- Structure Pipe, Oil Pipe, Gas Pipe

- Thickness

- 5 MM to 50 MM Millimeter (mm)

- Shape

- Round

- Standard

- ASTM

- Grade

- ASTM A106 Gr. A & B Seamless Pipes

- Outer Diameter

- 2 Inch to 24 inch Inch (in)

- Size

- 15 NB To 600 NB

- Length

- 3 Meter, 6 Meter, 9 Meter, 12 Meter & 18 Meters Meter (m)

Cs Astm A106 Grade A & B Seamless Pipe Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 50000 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per clients' requirements.

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Cs Astm A106 Grade A & B Seamless Pipe

Cs Astm A106 Grade A & B Seamless Pipe

Jagdish Metal Industries is known as a supplier of CS ASTM A106 Seamless Pipes. We supply various range of ASTM A106 Seamless Pipes Structural, Mechanical & Engineering applications. These pipes are made of premium quality steel alloy. These pipes are mostly used in the oil & gas industry and used in power plants and petrochemical applications. We provide the ASTM A106 Seamless Pipes in different sizes, shapes, & thicknesses to our valuable clients.

Versatile Applications Across Industries

CS ASTM A106 Grade A & B Seamless Pipes are ideal for use in multiple sectors, including construction, petrochemicals, oil and gas transport, and general structural purposes. Their robust construction and compliance with ASTM standards make them suited for projects requiring durability and reliability in both above-ground and underground installations.

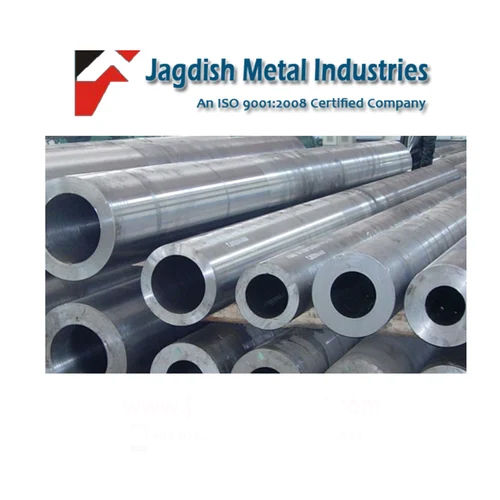

Precision Engineering and Durability

Manufactured from high-grade mild steel and available in a variety of thicknesses and diameters, these seamless pipes deliver exceptional pressure handling capability. The seamless design ensures uniform strength throughout the length of the pipe, reducing the risk of leaks or structural failure.

FAQ's of Cs Astm A106 Grade A & B Seamless Pipe:

Q: How are CS ASTM A106 Grade A & B Seamless Pipes manufactured?

A: These pipes are produced using premium mild steel, processed through a seamless manufacturing method which eliminates welds. This results in pipes with uniform mechanical strength and high reliability, following strict ASTM standards for quality.Q: What are the primary applications for these seamless pipes?

A: ASTM A106 Grade A & B Seamless Pipes are mainly used in structural frameworks, oil pipelines, and gas transportation systems. Their strength and corrosion resistance also make them suitable for process piping, boiler installations, and general industrial usage.Q: When should I choose Grade A over Grade B seamless pipe?

A: Grade A is preferred for applications with lower pressure and mild service requirements, while Grade B is ideal for higher pressure applications or situations demanding greater mechanical strength.Q: Where are these pipes typically supplied from in India?

A: These pipes are widely available from manufacturers, suppliers, and traders across India, catering to domestic and export markets. Major industrial hubs and metropolitan cities are primary distribution centers.Q: What is the process for selecting the appropriate pipe size and thickness?

A: Selection depends on factors like required pressure rating, application type, and installation environment. Consulting with a supplier can help determine the optimal outer diameter, thickness, and length for your specific needs.Q: How are these pipes commonly used in the oil and gas industry?

A: In oil and gas, ASTM A106 seamless pipes are valued for their ability to withstand high pressures and temperatures, efficiently transporting fluids and gases between processing stages with minimal risk of leakage or failure.Q: What are the main benefits of using seamless pipes over welded alternatives?

A: Seamless pipes offer superior structural integrity, uniform strength, and better pressure resistance due to the absence of welded joints. This leads to longer service life and increased safety, especially in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Pipe Category

Jindal Ms Pipe

Price 62 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Mild Steel Pipes

Shape : Round

Application : Construction

Type : Other, Seamless / ERW / Welded / Fabricated

MS Seamless Pipe ASTM A 106 GR. A

Price 89 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Mild Steel Pipes

Shape : Round

Type : Seamless

Rectangular Ms Pipe

Price 52 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Mild Steel Pipes

Shape : Rectangular

Application : Construction

Type : Seamless

CS Seamless Round Pipe ASTM A53 GR. A

Price 102 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Mild Steel Pipes

Shape : Round

Application : Construction

Type : Other, Seamless / ERW / Welded / Fabricated

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry